Vale receives the world’s first ore miner that produces air bubbles in the hull to reduce emissions

Jul, 01, 2021 Posted by Ruth HollardWeek 202127

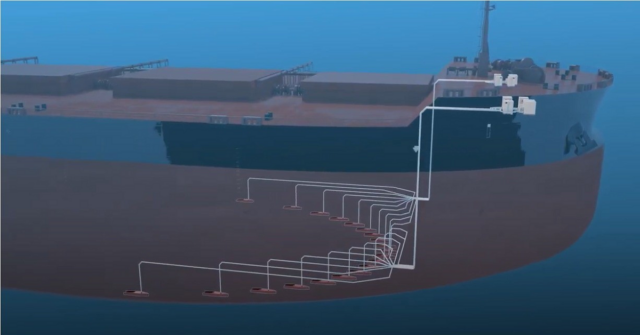

Air holes produced artificially under the ship’s hull will help Vale further reduce its greenhouse gas (GHG) emissions in navigation. The technology, known as air lubrication, was installed in the Sea Victoria, a Guaibamax with a capacity of 325 thousand tons. Ten compressors installed on the ship’s deck send air to twenty devices positioned under the ship that produce a carpet of bubbles. The action reduces the friction between the hull and the water, reducing fuel consumption and emissions. The Sea Victoria, which is already on its way to Brazil, is the first mineral carrier in the world to use this technology.

Vale’s navigation team estimates that the technology could be replicated throughout the entire fleet dedicated to the company’s service if it works out. “Conservative expectations point to a fuel reduction of around 5 to 8%, with a potential reduction of 4.4% in annual emissions from the maritime transport of iron ore at Vale”, explains the technical manager of Navigation, Rodrigo Bermelho.

The technology, supplied by the English manufacturer Silverstream, is a project developed by Vale’s navigation area in cooperation with the Vale Technological Institute and in partnership with the Korean shipowner Pan Ocean for installation in one of its VLOCs (Very Large Ore Carriers). Shanghai Ship Design Research Institute (SDARI) was responsible for the ship design and integration with the bubbles. The Chinese shipyard New Times Shipbuilding prepared the vessel during its construction. The shipyard Yiu Lian Dockyards (Shekou) LTD, located in the Chinese city of Shenzhen, conducted the equipment installation. The installation lasted 35 days, and the ship was ready on June 28th.

The adoption of air lubrication is part of Ecoshipping, a program created by Vale to meet the challenge of reducing its carbon emissions in alignment with the International Maritime Organization (IMO). Last year, the company announced that it intends to neutralize its direct and indirect emissions (scopes 1 and 2) by 2050 and reduce scope 3 emissions by 15% by 2035, related to its value chain, affecting its shipping emissions since the ships are not their own. The goals are in line with the ambition of the Paris Agreement. Workers receive one of ten compressors installed on the ship’s deck, which send air to twenty devices positioned underneath the ship and produce a carpet of bubbles.

-

Ports and Terminals

Nov, 14, 2019

0

Santos Brasil announced a net profit of R$7.7m in 3Q19

-

Aug, 17, 2021

0

The US exports the same amount of beef as Brazil, but earns much more

-

Trade Regulations

Sep, 26, 2022

0

China advances FTA strategy

-

Ports and Terminals

Feb, 01, 2024

0

Itaqui Port welcomes Japanese ambassador in talks for new investments